US

Military are using smart metals similar

to those found at the Roswell Crash In

1947

"Time is ripe for the insertion of smart structures and materials

into space systems."

Dr. Keith

Denoger

Airforce Research

Laboratories

"Imagine seeing a

bullet shot through a sheet of material, only to have the material instantly

"heal" behind the bullet! Remember, this is not science fiction. Self-healing

materials actually exist, and LaRC scientists are working to unravel their

secrets.

What we did at NASA-Langley was

basically dissect that material to answer the question, 'how does it do that?'"

McGowan said. "By doing so, we can actually get down to computational modeling

of these materials at the molecular level. Once we understand the material's

behavior at that level, then we can create designer 'smart'

materials,"

Anna McGowan,

Program Manager for the Morphing

Project at NASA's Langley Research Center.

Does the above quote

sound familiar? Metal that is cut, only to 'heal' itself? We have all become

accustomed to hearing about technological advances that were initially

spearheaded by secret military research projects. The Atom Bomb was developed

during the Second World War amid incredibly tight security, and the first most

people knew about Stealth technology was when the bat-like fighter-bombers were

being rolled out of the hangers to attack the military apparatus of Iraq. Many

of us are expecting a new dawn of technological wizardry to make its debut

appearance during the current ‘war on terrorism’.

Cosmic

Conspiracies would like to share with you some remarkable information

relating to current cutting-edge technological research being conducted on

behalf of the U.S. military that we believe could be connected to the materials

found from the Roswell crash. We are stunned by it, not least because of how

freely available much of the data is on the Internet. Finding this freely

available material, however, is extremely difficult unless you are aware of the

specific keywords being utilised, or, as in our case, you have a researcher of

the calibre of Martin Cosnette. This is not common

knowledge, despite the amazing jump in technology implied by the rapid advances

being made right now.

Cosmic

Conspiracies would like to share with you some remarkable information

relating to current cutting-edge technological research being conducted on

behalf of the U.S. military that we believe could be connected to the materials

found from the Roswell crash. We are stunned by it, not least because of how

freely available much of the data is on the Internet. Finding this freely

available material, however, is extremely difficult unless you are aware of the

specific keywords being utilised, or, as in our case, you have a researcher of

the calibre of Martin Cosnette. This is not common

knowledge, despite the amazing jump in technology implied by the rapid advances

being made right now.

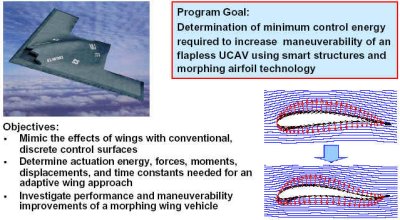

Click on the picture below to see a simulation of what the smart materials will be used for.

Click to download Quicktime

Movie Player

Image courtesy of

Robert C. Byrd National Technology Transfer Center.

The

above picture is an artists impression that was drawn from witness' accounts

of the Roswell craft. We think its uncanny how similar it looks to the craft in the movie

simulation which was recently released by NASA! The image was drawn by William Louis McDonald and

taken from the book 'The Encyclopedia of Extraterrestrial Encounters', by Ronald

Story, 2001.

Amazing advances are being made in the development of new metal

alloys. These alloys have remarkable characteristics, in that they will change

shape upon the application of an electric current or magnetic field. They change

shape, or ‘morph’ as the researchers prefer to say, rapidly and with some

considerable force. They are termed ‘compact hybrid actuators’, a mouthful of

engineering jargon, so we would prefer to call them ‘living metals’. Why?

Because these alloys incorporate advanced nano-technology that is designed to

enable them to mimic living systems in their versatility and dynamism. The list

of potential applications seems endless, and the U.S. military is funding a

variety of related research programs exploring the full range of options.

Self-healing wings that flex and react like living organisms, versatile bombers

that double as agile jet fighters, and swarms of tiny unmanned aircraft are just

a few of the science-fiction-like possibilities that these next-generation

technologies could make feasible in the decades ahead.

Just so that you don’t

think this all sounds like drawing-board ideas being dreamt up by some egg-head

think-tank, there is a considerable body of evidence to show that the testing

stage for some of these alloys has already taken place.

We have accessed over 130

documents so far, including pictures and video footage, budgets and names of

project leaders and their departments/companies involved. This technology is

being incorporated into prototype applications right now. These include morphing

aeroforms in Unmanned Aerial Vehicles (UAVs) and fighter aircraft, morphing

rotor-blades in helicopters, in-flight navigation, guidance and control systems

for small missiles, satellite technology (especially with respect to optical

systems), and sonar-absorbing materials for submarines. If you watch the video

animation above, you will see that a plane with flappable wings is one of the

goals of this project.

We have accessed over 130

documents so far, including pictures and video footage, budgets and names of

project leaders and their departments/companies involved. This technology is

being incorporated into prototype applications right now. These include morphing

aeroforms in Unmanned Aerial Vehicles (UAVs) and fighter aircraft, morphing

rotor-blades in helicopters, in-flight navigation, guidance and control systems

for small missiles, satellite technology (especially with respect to optical

systems), and sonar-absorbing materials for submarines. If you watch the video

animation above, you will see that a plane with flappable wings is one of the

goals of this project.

These active and complex metal

alloys are being designed to be used in ‘exo-skeletons’ to be worn by

battle-field soldiers, creating ‘Robo-cop’ style advances in G.I. Joe’s combat

performance.

The U.S. Military are currently inviting applications for between

$30-40m of research grants to find ways of facilitating neural transmission

between the soldier’s brain waves and his living metal exo-skeleton. They are

not expecting mere ‘incremental’ progress, either. The projects are 3-year terms

in length, and many of them are nearing completion or are already accomplished.

There is a palpable sense of urgency to this research, and we think this

reflects the rapid advances being made in these projects.

The research is being

conducted by a number of private-sector aerospace consortiums (including the

likes of Boeing, M.I.T., Moog and Lockheed Martin), as well as several

university departments in receipt of grants from the U.S. Military.

The entire

project is being supported by the following military organisations: the US Army

Research Office, the Office Of Naval Research, NASA Langley Research Center

(yes, they’re military too!), and (wait for it…) the Space Operations Vehicle

Technology Office, AFRL/VAS at Wright Patterson AFB.

As you probably already

know, there's a hangar at Wright Patterson Air Force base that contains

very highly classified material, believed to be Roswell and/or other ET remains,

so tightly controlled that even Barry Goldwater, a US Senator and Major General

in the USAF Reserve, was denied access.We are intrigued by this final

link, as you will see in our discoveries below!

Other projects that

involve the shape memory alloys include vortex wake control (vortex tabs on

control planes), smart wings, smart skins (self and radiated noise cancellation)

smart panel (structure acoustic and vibration isolation) and they are to be used

in the construction of space laser weapons in the future.

Morphing Project Program Manager lets slip that the

smart materials they are working on could be back

engineered!

We were staggered at the

remarks on Langleys AFB website made by Anna McGowan, program manager for the

Morphing Project at NASA's Langley Research Center (which is a part of this

project, but not the main company).

She says:

"Among the exotic "smart" materials being developed by the

Morphing Project, shape-memory alloys are relatively ordinary. Imagine seeing a

bullet shot through a sheet of material, only to have the material instantly

"heal" behind the bullet! Remember, this is not science fiction. Self-healing

materials actually exist, and LaRC scientists are working to unravel their

secrets.

"What we did at NASA-Langley was basically dissect that

material to answer the question, 'how does it do that?'" McGowan said. "By doing

so, we can actually get down to computational modeling of these materials at the

molecular level. Once we understand the material's behavior at that level, then

we can create designer 'smart' materials," she added.

LaRC is also developing customized variations of piezoelectric

materials. These substances link electric voltage to motion. If you contort a

piezoelectric material a voltage is generated. Conversely, if you apply a

voltage, the material will contort.

The above statement seems

odd to us. Why would you strip down technology to see how it works if you had

built it in the first place? Or does this mean that NASA-Langley did not make

the material, but are in fact back-engineering it?

M o r p h i n g M e t a l

sWe've waited a little while before releasing

this information. That was partly because we wondered whether the head of

the Compact Hybrid Actuation Program (CHAP) would reply to our extensive

questions, and partly because of the following:

When we first made it known that we

thought we had come across something awesome to do with advanced ‘morphing

metal’ technology, there was some mention that this was already common

knowledge. We assumed, then, that other researchers and commentators, who

had questioned our judgement, would come forward with the references and data

that we had discovered, and ‘show us up’, as we say here in Britain.

Instead, we have had many people asking us when we’re releasing our data, and no

one showing us how this is an ‘old story’.

Now, we are not

omnipotent. There may be some people out there who know all about this

already, but the feedback we have received indicates that, to the vast majority

of people out there, this is entirely new material. No one else is carrying this

story except Cosmic Conspiracies. If that’s because they don’t think it’s

important, then that’s up to them. We have been interested in UFOlogy for

some considerable time, and read a lot of material, both in magazines and

on-line, and this material is news to us. We remain excited by it, not

necessarily because it individually blows the lid off the ‘seeding technology’

business between the US Military and private industry/academic research labs,

but because, taken in the context of the claims of Colonel Philip Corso and

others, it adheres to a pattern that is noticeable, and significant.

Now, we are not

omnipotent. There may be some people out there who know all about this

already, but the feedback we have received indicates that, to the vast majority

of people out there, this is entirely new material. No one else is carrying this

story except Cosmic Conspiracies. If that’s because they don’t think it’s

important, then that’s up to them. We have been interested in UFOlogy for

some considerable time, and read a lot of material, both in magazines and

on-line, and this material is news to us. We remain excited by it, not

necessarily because it individually blows the lid off the ‘seeding technology’

business between the US Military and private industry/academic research labs,

but because, taken in the context of the claims of Colonel Philip Corso and

others, it adheres to a pattern that is noticeable, and significant.

So we will leave it to others

whether this is news-worthy, or otherwise. We’ve given others the chance

to break this story if they think we are trawling over old ground, and they

haven’t. This is a story that we think should be heard. So here it

is…

These summaries of ‘morphing metal’

technologies have been gleaned from the extensive DARPA site, the cutting edge

research organisation that is part of the U.S. military. The

‘state-of-play’ that is described on the surface is incredible enough, but when

you start to dig a little deeper, and put a few connections together, the full

potential for this technology becomes self-evident.

1. "DARPA and the ARO have been

developing active control applications of smart materials and structures over

the last 6 years" (2000). So although this is a relatively recent programme

exploring the potential for these technologies, the degree of practical

application already managed would suggest an exciting level of success. The

DARPA organisation directs cutting edge research which is initially speculative,

with a high probability of failure, but also with the potential for occasional

bursts of brilliance.

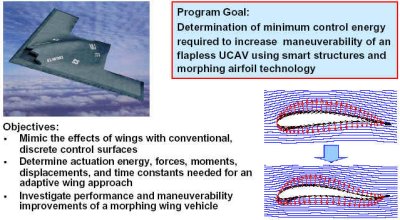

2. The actuators currently used in

the wings of certain aircraft are facilitating 'morphing airfoil technology',

whereby the shape of the aero-form can be altered mid-flight to maximize a

particular manouevre or flight performance. "Adding the active

member into the control system significantly increases the controllability of

the torsional modes for a marginal (0.1%) increase in power."

Military researchers and developers are succeeding in making aero-forms with

wings that change shape with very little power usage, and no moving

parts.

So, in the case of a fighter

aircraft or UAV (Unmanned Aerial Vehicle), the variability of the shape of the

aero-form allows optimization for both 'subsonic interdiction' and also

'supersonic intercept missions'. In other words, an aircraft could assume one

shape for flying towards a mission target, then take on another form for

performing more rigorous manouevres when in action. This extends mission

performance significantly. This is well known in some quarters, although

it may still surprise many. But, from what we have been reading, we think

that this is the tip of the ice-berg!

The actuation devices enable

surfaces to be controlled without the need for a traditional steering mechanism

or driving hardware, increasing performance and structural stability. The

devices are electrically driven, delivering a high force potential quickly. In

practice, the shape of the wing actually re-contours whilst under significant

external stresses, and then returns to its rest position without displacement

after the applied electrical current has been stopped. In the case of missiles,

thin film shape memory alloys might be used in nose control systems as compact

navigation, guidance and control technologies.

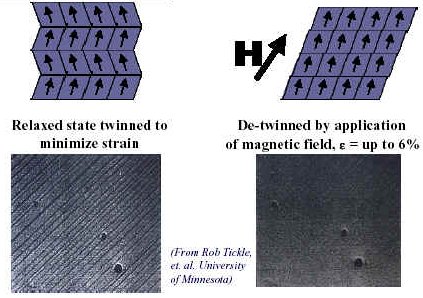

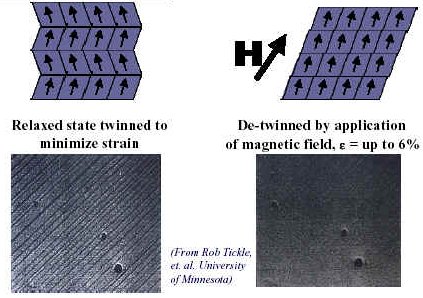

3. Various alloys have been

developed that retain a shape memory. Some of these actuators perform

mechanically upon the application of a magnetic field only. For instance,

that NiTinol, Ni-free Titanium and ferromagnetic Smart Memory Alloys can be

"energized by [a] magnetic field". We think that this property may

certainly have a connection with UFO technology, insofar as it has been

generally reported; unidentified aero-forms that change shape mid-flight, and

have hazy appearances that relate to an energy field pervasive around the UFO at

the time. There are many magnetic anomalies reported by witnesses and

researchers, and a correlation between changing form and magnetic field effects

appears to be an important consideration.

4. A non-military application that

has been cited by CHAP researchers (who may be anxious to see their research put

to some beneficial use) is in the use of Braille. We understand this to mean

that 'writing' could be induced upon a smooth metallic surface, that can then

return to its flattened states for continual reuse. One can then imagine a

scrolling metallic script upon a metal interface that will allow Braille readers

to access, say, an electronic book with ease. It is a wonderful

possibility.

5. It is mentioned that the

architectures of the actuators are complex, and an allusion to an ‘organic

system’ is given when talking about some of these remarkable metal alloys.

Upon the stimulus of an external command the powered actuator will be able to

produce a mechanical force autonomously, and respond to a degree of complexity

hitherto unimagined. Given the incredible leaps in information technology

that have been made over the past couple of decades, the level of command detail

for a ‘morphing metal’ is very great indeed. If they are as adaptive as is

being reported in the scientific papers, then their flexibility could certainly

mimic living systems, like muscles. For instance, this quote is made by

the Sarcos research team:

"These new actuators are similar

in architecture to biological systems (elements arranged in parallel-series

assemblies), but use very different building blocks. As in biological systems,

the individual elements are optimized for best performance around one operating

point…

"The small

elements forming these actuation system achieve high power and energy density by

using combustible fuel energy sources and efficient energy conversion via

oscillatory and sometimes resonant processes. The power produced by the sources

will be modulated at the individual element level rather by means of lossy

components such as valves and power transistors, thereby providing power on

demand with low power quiescent state. By using a modular architecture where

many similar or identical elements are used, mass production methods becomes

possible and economies of scale can be achieved. This approach, which we

designate as Organismic Systems, is characterized by the use of many elements

which are systematically interconnected in terms of structure, physical effort,

and information."

The power to drive the actuators is

portable, and could, for instance, take the form of a back-pack worn by soldiers

who are powered lower body exoskeletons. But there are hints in the

research texts alluding to truly 'intelligent' materials. We consider it likely

that the modular architecture described fits in with the general concepts of

'nano-technology'. That is, the intelligent ‘biological’ actuators have

purpose-built machines within it designed at the molecular level.

The power to drive the actuators is

portable, and could, for instance, take the form of a back-pack worn by soldiers

who are powered lower body exoskeletons. But there are hints in the

research texts alluding to truly 'intelligent' materials. We consider it likely

that the modular architecture described fits in with the general concepts of

'nano-technology'. That is, the intelligent ‘biological’ actuators have

purpose-built machines within it designed at the molecular level.

This then takes on an altogether

new dimension when placed in the context of proposed brain implants that can

pick up neurological information directly. This information could then

readily be transferred to the ‘morphing metal’ interface that will be quite

capable of adapting to the complex commands delivered by the brain. One

can imagine the development of prosthetic limbs made of these alloys that

receive direct instruction from the wearer’s brain, and therefore react like

real limbs. The military applications are obviously quite incredible, and

this might very well explain why $30-40m of military funding is up for grabs to

develop this kind of neuro-control technology.

6. Finally, compact hybrid actuators are

being developed to reduce levels of self-noise, particularly with respect to the

sonar detectibility of torpedoes. Mention is also made of Unmanned Underwater

Vehicles (I presume this is what is meant by UUV's). This technology seems

to represent a kind of 'stealth' characteristic for underwater vehicles and

weapon systems. One wonders whether a similar system has been applied to ground

or air vehicles to effectively 'cloak' them on an auditory level?

6. Finally, compact hybrid actuators are

being developed to reduce levels of self-noise, particularly with respect to the

sonar detectibility of torpedoes. Mention is also made of Unmanned Underwater

Vehicles (I presume this is what is meant by UUV's). This technology seems

to represent a kind of 'stealth' characteristic for underwater vehicles and

weapon systems. One wonders whether a similar system has been applied to ground

or air vehicles to effectively 'cloak' them on an auditory level?

Certainly, it is known that there

are ‘silent’ helicopters, and ground vehicles used by special forces units that

have stealth characteristics.

These current applications might

lead us to suspect that the progress in this technology that has been officially

released by DARPA, and the ‘actual’ state of play are two entirely separate

things. This will not be a surprise to anyone, of course, and one would

expect the U.S. Military to keep their latest leaps in technology under wraps

for when they are actually needed. But this could certainly indicate that

what we are presenting as ‘state-of-the-art’ in morphing metals is actually

nothing of the kind. Which then allows us to consider the ‘proposed’

future advancements with just a little scepticism. Are we simply being

‘drip-fed’ with information about remarkable leaps in material technologies that

are just around the corner?

Think about it…why are DARPA making

all this information publicly available when these projects represent

cutting-edge military research and development? They didn’t do that with

Stealth. We think there is much more to come, but you can take a look and

judge for yourself. Become informed, because we think this ‘material’ will

become a big part of your life sooner than you think…

Shape Memory

Alloys

As incredible

as it sounds, material scientists conducting research projects for the American

military are successfully creating metals that can not only change shape upon

the application of an energy field, but that might soon be able to autonomously

‘self-actuate’! Are we on the verge of creating intelligent alloy

materials that have their own memory and motion capabilities? Is this

scientific progress an indirect result of the now infamous exotic materials that

once fell into the hands of the US Government in 1947?

The following executive report explains the state

of the art ‘intelligent material’ science produced by a University of

Washington-based research group for CHAP, a highly ambitious materials research

project commissioned by DARPA, the Defense Advanced Research Projects

Agency:

Development of Compact Hybrid Actuators Based on

Ferromagnetic Poly-crystal Fe-Pd Material

“The goal of the UW-Instron-DOE Albany project

is the design of a robust compact actuator based on polycrystalline

ferromagnetic shape memory alloy (FSMA) materials. " New materials will also

be investigated. A preliminary study of a proof-of-concept device has been

completed and is described below:

“…The ductile nature of the polycrystalline

Fe-Pd allows it to be processed into any 3-D shape, including springs, by using

conventional processing methods, which would be quite cost effective.

[There is a] rapid actuation of the polycrystalline Fe-Pd spring driven by a

portable magnet: the large stroke achieved with application of the magnetic

field is clearly seen. In this project, a more compact electromagnetic

system housed inside the Fe-Pd spring will be developed. In addition, new

material compositions will be investigated, including Fe-Pd-Pt for a more

noticeable shape memory effect and better superelasticity behavior and

Fe-Ti-Co-Ni for cost.

“After improving the performance of the Fe-Pd

spring actuator, a proto type will be built and demonstrated for Phase 1.

The prototype unit will consist of a Fe-Pd spring actuator (L=15cm, dia=3cm), an

electromagnetic driving unit to be housed inside the spring, and a position

sensor with a central unit. This device is expected to provide up to a

10cm stroke capability with a relatively large force (150N).”

In a response to: Solicitation BAA00-03: Compact

Hybrid Actuation Program (CHAP)

Prime

Contractor: University of Washington

Dr.

Minoru Taya, PI, Professor and Director

Center for Intelligent Materials and System

Department of Mechanical Engineering

University of Washington

These Iron-Palladium alloys are clearly capable of

remarkable shape-changing feats already. The investigating team is now

attempting to integrate further ‘intelligent’ components into the alloy, such

that there will be no requirement for an external energy field to be applied to

the metal to make it reshape. Is this nano-technology at work? The

metal itself will incorporate an ‘electromagnetic driving unit’ and, presumably,

a ‘position sensor with a central unit.’

How large is the Fe-Pd spring actuator? Just 15cm

length by 3 cm diameter. Yet this spring will become an intelligent

autonomous machine with a remarkable tensile strength and stroke

capability. It will have its own ‘shape memory’.

Where have we heard of this kind of exotic

material before? Before answering this question, let us explore the nature

of these remarkable new materials a little more.

The Sarcos research team describes these new forms of

actuator in this way:

“These new actuators are similar in

architecture to biological systems (elements arranged in parallel-series

assemblies), but use very different building blocks. As in biological systems,

the individual elements are optimized for best performance around one operating

point…

“The small elements forming these actuation

system achieve high power and energy density by using combustible fuel energy

sources and efficient energy conversion via oscillatory and sometimes resonant

processes. The power produced by the sources will be modulated at the individual

element level rather by means of lossy components such as valves and power

transistors, thereby providing power on demand with low power quiescent state.

By using a modular architecture where many similar or identical elements are

used, mass production methods becomes possible and economies of scale can be

achieved. This approach, which we designate as Organismic Systems, is

characterized by the use of many elements which are systematically

interconnected in terms of structure, physical effort, and

information.”

In other words, these metals are essentially

machines that are built at the elemental level, and have complex internal

architecture and systems in a similar way to living ones. The

nano-machines incorporated into the metal alloys utilize energy sources at the

‘individual element level’. The metal alloy actuators are essentially

autonomous. This is very remarkable indeed, particularly given the

accounts of those who have come into contact with materials alleged to be of an

extra-terrestrial nature.

The Roswell

Artifacts

In the

latest research update by Thomas J. Carey & Don R. Schmitt regarding the

Roswell case, they describe up to 9 types of exotic materials variously reported

by witnesses to the events of July 1947 in New Mexico. One of these types

of metal has particular relevance here:

“An unknown quantity of very small to

hand-sized pieces of a very thin and very light “metal” that displayed both

solid and “fluid” qualities. The colour of dull aluminium, a piece of it

could be wadded up like a ball in one’s hand [without any sensation of weight]

and, when placed on a flat surface, it unfurled [“flowed like water”] to its

original flat, seamless shape without a mark on it. Also extremely tough,

it could not be cut, scratched or burned.

“Note: it is this so called ‘memory metal’ that

our investigation today refers to as the ‘Holy Grail’ of Roswell since a piece

of it, if found, would in our view constitute irrefutable proof that an

extraterrestrial spacecraft had been recovered.” (UFO Magazine

Sept/Oct 2000 p62)

Perhaps, if the CHAP project continues to make the

rapid progress that it has been in recent years, such material might not be

solely the domain of extra-terrestrial visitors to our planet. Could

Compact Hybrid Actuators be the terrestrial equivalent of the Roswell

artifacts? Indeed, is it possible that the various research organisations

engaged in the production of this kind of material are being surreptitiously

guided towards this outcome? Perhaps there are good reasons for believing

so…

Colonel

Corso

In his controversial book ‘The Day After Roswell’

Col. Philip J. Corso (Ret.), the former head of the Foreign Technology Desk at

the U.S. Army’s Research and Development department, described his own

experience of examining similar material alleged to come from the 1947 crash

site:

“There was a dull, greyish-silvery foil-like

swatch of cloth among these artifacts that you could not fold, bend, tear, or

wad up but that bounded right back into its original shape without any

creases. It was a metallic fibre with physical characteristics that would

later be called “supertenacity,” but when I tried to cut it with scissors, the

arms just slid right off without even making a nick in the fibres. If you

tried to stretch it, it bounced back, but I noticed that all the threads seemed

to be going in one direction. When I tried to stretch it width-wise

instead of length-wise, it looked like the fibres had re-orientated themselves

to the direction I was pulling in. This couldn’t be cloth, but it

obviously wasn’t metal. It was a combination, to my unscientific eye, of a

cloth woven with metal strands that had the drape and malleability of a fabric

and the strength and resistance of a metal. I was on top of some of the

most secret weapons projects at the Pentagon, and we had nothing like this, even

under the wish-list category.” (The

Day After Roswell, p49 Pocket Books 1997)

Although this appears to be a variant on the

metallic artifacts reported by Roswell witnesses, Corso’s account is no less

interesting for that, particularly given his claims about what happened to this

material. In keeping with his own role as the ‘seeder’ of the Roswell

technologies to the giants of American industry, the ‘supertenacious fibres’

allegedly found there way to the research departments of Monsanto and Dow

(p235). Furthermore, Corso claims that the material had previously been

delivered to the Air Materiel Command at Wright Field (p236). Wright

Patterson Air Force Base, as it is now known, is famous in UFO circles for its

Foreign Technology division, purported to hold extra-terrestrial craft and

artifacts (See ‘Above Top Secret: The Worldwide UFO Cover-up by Timothy Good,

1988).

Department of

Defense Collaborator

Given this persistent rumour about the hidden work

conducted at Wright Patterson AFB, then it is certainly quite remarkable that

this particular base should feature among a select band of DoD collaborators for

the CHAP research:

“Several other Department of Defense (DoD)

agencies conduct research related to DARPA's work in the area of Compact Hybrid

Actuators. The following DoD collaborators serve as information resources to the

program, promoting knowledge sharing among research teams:

1. Gary L. Anderson

US Army Research Office

2.

3. Roshdy

George S. Barsoum, PhD, PE

Office Of Naval

Research

4. David B. Homan, Deputy Program Manager

Space Operations Vehicle Technology Office

AFRL/VAS

Wright Patterson AFB,

5. Garnett Horner

NASA Langley Research Center”

Does the role of the ‘Space Operations Vehicle

Technology Office’ at Wright Patterson AFB here specifically involve ‘seeding’

information about ‘memory metals’ to the CHAP research teams? This must be

a strong possibility.

UPDATE September

2002

| It seems that

the CHAP project is steaming away at full power since we first learnt of

it in December, 2001. This article was posted recently on NASA's

research site at http://www.ipt.arc.nasa.gov/spacetransport.html

We

thought you would enjoy reading the new developments, including plans

for space vehicles to be able to repair themselves mid-flight. Don't say

we didn't tell you so!

Dave

at Cosmic Conspiracies...

Revolutions in technology--like the

Industrial Revolution that replaced horses with cars--can make what

seems impossible today commonplace tomorrow.

Such a revolution is happening right now. Three of the fastest-growing

sciences of our day--biotech, nanotech, and information technology--are

converging to give scientists unprecedented control of matter on the

molecular scale. Emerging from this intellectual gold-rush is a new

class of materials with astounding properties that sound more at home in

a science fiction novel than on the laboratory workbench.

Imagine, for example, a substance with 100 times the strength of steel,

yet only 1/6 the weight; materials that instantly heal themselves when

punctured; surfaces that can "feel" the forces pressing on

them; wires and electronics as tiny as molecules; structural materials

that also generate and store electricity; and liquids that can instantly

switch to solid and back again at will. All of these materials exist

today ... and more are on the way.

With such mind-boggling materials at hand, building the better

spacecraft starts to look not so far fetched after all.

Weight equals money

The challenge of the

next-generation spacecraft hinges on a few primary issues. First and

foremost, of course, is cost.

"Even

if all the technical obstacles were solved today, exploring our solar

system still needs to be affordable to be practical," says Dr.

Neville Marzwell, manager of Revolutionary Aerospace Technology for

NASA's Next Decadal Planning Team. "Even

if all the technical obstacles were solved today, exploring our solar

system still needs to be affordable to be practical," says Dr.

Neville Marzwell, manager of Revolutionary Aerospace Technology for

NASA's Next Decadal Planning Team.

Lowering the cost of space flight primarily means reducing weight. Each

pound trimmed is a pound that won't need propulsion to escape from

Earth's gravity. Lighter spaceships can have smaller, more efficient

engines and less fuel. This, in turn, saves more weight, thus creating a

beneficial spiral of weight savings and cost reduction.

Right: This fully-loaded Saturn V

moon rocket weighed 6.2 million pounds. It was heavy and expensive to

launch. [more]

The challenge is to trim weight while increasing

safety, reliability, and functionality. Just leaving parts out won't do.

Scientists are exploring a range of new technologies that could help

spacecraft slim down. For example, gossamer materials--which are

ultra-thin films--might be used for antennas or photovoltaic panels in

place of the bulkier components used today, or even for vast solar sails

that provide propulsion while massing only 4 to 6 grams per square

meter.

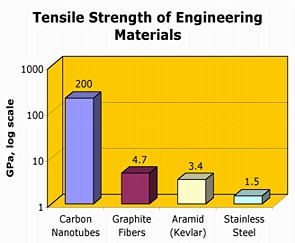

Composite materials, like those used in carbon-fiber tennis rackets and

golf clubs, have already done much to help bring weight down in

aerospace designs without compromising strength. But a new form of

carbon called a "carbon nanotube" holds the promise of a

dramatic improvement over composites: The best composites have 3 or 4

times the strength of steel by weight--for nanotubes, it's 600 times!

"This

phenomenal strength comes from the molecular structure of nanotubes,"

explains Dennis Bushnell, a chief scientist at Langley Research Center (LaRC),

NASA's Center of Excellence for Structures and Materials. They look a

bit like chicken-wire rolled into a cylinder with carbon atoms sitting

at each of the hexagons' corners. Typically nanotubes are about 1.2 to

1.4 nanometers across (a nanometer is one-billionth of a meter), which

is only about 10 times the radius of the carbon atoms themselves. "This

phenomenal strength comes from the molecular structure of nanotubes,"

explains Dennis Bushnell, a chief scientist at Langley Research Center (LaRC),

NASA's Center of Excellence for Structures and Materials. They look a

bit like chicken-wire rolled into a cylinder with carbon atoms sitting

at each of the hexagons' corners. Typically nanotubes are about 1.2 to

1.4 nanometers across (a nanometer is one-billionth of a meter), which

is only about 10 times the radius of the carbon atoms themselves.

Left: The lattice of carbon atoms in a carbon nanotube is

like a peg-board for hanging other kinds of atoms and molecules to give

the nanotube special chemical, electrical or thermal properties.

Copyright Prof.

Vincent H. Crespi Department of Physics Pennsylvania State

University. [more]

Nanotubes were only discovered in 1991,

but already the intense interest in the scientific community has

advanced our ability to create and use nanotubes tremendously. Only 2 to

3 years ago, the longest nanotubes that had been made were about 1000

nanometers long (1 micron). Today, scientists are able to grow tubes as

long as 200 million nanometers (20 cm). Bushnell notes that there are at

least 56 labs around the world working to mass produce these tiny tubes.

"Great strides are being made, so making bulk materials using

nanotubes will probably happen," Bushnell says. "What we don't

know is how much of this 600 times the strength of steel by weight will

be manifest in a bulk material. Still, nanotubes are our best bet."

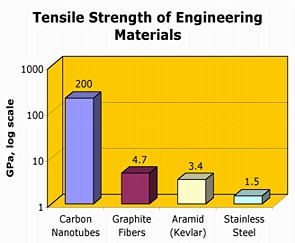

Right:

The tensile strength of carbon nanotubes greatly exceeds that of

other high-strength materials. Note that each increment on the vertical

axis is a power of 10. [more] Right:

The tensile strength of carbon nanotubes greatly exceeds that of

other high-strength materials. Note that each increment on the vertical

axis is a power of 10. [more]

Beyond merely being strong, nanotubes

will likely be important for another part of the spacecraft weight-loss

plan: materials that can serve more than just one function.

"We used to build structures that were just dumb, dead-weight

holders for active parts, such as sensors, processors, and

instruments," Marzwell explains. "Now we don't need that. The

holder can be an integral, active part of the system."

Imagine that the body of a spacecraft could also store power, removing

the need for heavy batteries. Or that surfaces could bend themselves,

doing away with separate actuators. Or that circuitry could be embedded

directly into the body of the spacecraft. When materials can be designed

on the molecular scale such holistic structures become possible.

Spacecraft skins

Humans can feel even the slightest

pinprick anywhere on their bodies. It's an amazing bit of

self-monitoring--possible because your skin contains millions of

microscopic nerve endings as well as nerves to carry those signals to

your brain.

Likewise, materials that make up critical

systems in a spaceship could be embedded with nanometer-scale sensors

that constantly monitor the materials' condition. If some part is

starting to fail--that is, it "feels bad"--these sensors could

alert the central computer before tragedy strikes.

Molecular

wires could carry the signals from all of these in-woven sensors to the

central computer, avoiding the impractical bulk of millions and millions

of today's wires. Again, nanotubes may be able to serve this role.

Conveniently, nanotubes can act as either conductors or semi-conductors,

depending on how they're made. Scientists have made molecular wires of

other elongated molecules, some of which even naturally self-assemble

into useful configurations. Molecular

wires could carry the signals from all of these in-woven sensors to the

central computer, avoiding the impractical bulk of millions and millions

of today's wires. Again, nanotubes may be able to serve this role.

Conveniently, nanotubes can act as either conductors or semi-conductors,

depending on how they're made. Scientists have made molecular wires of

other elongated molecules, some of which even naturally self-assemble

into useful configurations.

Above: This piezoelectric

material, developed at NASA's Langley Research Center (LaRC), can

"feel" deformations such as bending or surface pressure,

producing a small voltage in response that can act as a signal for a

central computer. Image courtesy NASA's Morphing Project at LaRC.

Your skin is also able to heal itself. Believe it or not, some advanced

materials can do the same thing. Self-healing materials made of

long-chain molecules called ionomers react to a penetrating object such

as a bullet by closing behind it. Spaceships could use such skins

because space is full of tiny projectiles--fast-moving bits of debris

from comets and asteroids. Should one of these sand- to pebble-sized

objects puncture the ship's armor, a layer of self-healing material

would keep the cabin airtight.

Meteoroids aren't the only hazard; space is filled with radiation, too.

Spaceships in low-Earth orbit are substantially protected by our

planet's magnetic field, which forms a safe bubble about 50,000 km wide

centered on Earth. Beyond that distance, however, solar flares and

cosmic rays pose a threat to space travelers.

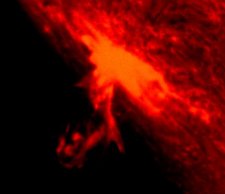

Right:

A solar flare blasts energetic radiation into space. [more] Right:

A solar flare blasts energetic radiation into space. [more]

Scientists are still searching for a good

solution. The trick is to provide adequate shielding without adding lots

of extra weight to the spacecraft. Some lightweight radiation-shielding

materials are currently being tested in an experiment called MISSE

onboard the International Space Station. But these alone won't be

enough.

The real bad guy is Galactic Cosmic

Radiation (GCR) produced in distant supernova explosions. It consists,

in part, of very heavy positive ions--such as iron nuclei--zipping along

at great speed. The combination of high mass and high speed makes these

little atomic "cannon balls" very destructive. When they

pierce through the cells in people's bodies, they can smash apart DNA,

leading to illness and even cancer.

"It turns out that the worst materials you can use for shielding

against GCR are metals," Bushnell notes. When a galactic comic ray

hits a metallic atom, it can shatter the atom's nucleus--a process akin

to the fission that occurs in nuclear power plants. The secondary

radiation produced by these collisions can be worse than the GCR that

the metal was meant to shield.

Ironically, light elements like hydrogen

and helium are the best defense against these GCR brutes, because

collisions with them produce little secondary radiation. Some people

have suggested surrounding the living quarters of the ship with a tank

of liquid hydrogen. According to Bushnell, a layer of liquid hydrogen 50

to 100 cm thick would provide adequate shielding. But the tank and the

cryogenic system is likely to be heavy and awkward.

Here

again, nanotubes might be useful. A lattice of carbon nanotubes can

store hydrogen at high densities, and without the need for extreme cold.

So if our spacecraft of the future already uses nanotubes as an

ultra-lightweight structural material, could those tubes also be loaded

up with hydrogen to serve as radiation shielding? Scientists are looking

into the possibility. Here

again, nanotubes might be useful. A lattice of carbon nanotubes can

store hydrogen at high densities, and without the need for extreme cold.

So if our spacecraft of the future already uses nanotubes as an

ultra-lightweight structural material, could those tubes also be loaded

up with hydrogen to serve as radiation shielding? Scientists are looking

into the possibility.

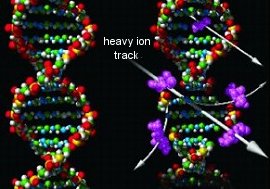

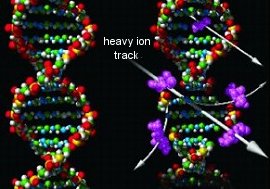

Above: When high-energy

cosmic rays crash into astronauts' DNA, it can cause damage leading to

cancers or other radiation-induced illnesses. Images courtesy NASA's Office

of Biological and Physical Research.

Going one step further, layers of this structural material could be

laced with atoms of other elements that are good at filtering out other

forms of radiation: boron and lithium to handle the neutrons, and

aluminum to sop up electrons, for example.

Camping out in the cosmos

Earth's surface is mostly safe from cosmic radiation, but other planets

are not so lucky. Mars, for example, doesn't have a strong global

magnetic field to deflect radiation particles, and its atmospheric

blanket is 140 times thinner than Earth's. These two differences make

the radiation dose on the Martian surface about one-third as intense as

in unprotected open space. Future Mars explorers will need radiation

shielding.

"We

can't take most of the materials with us for a long-term shelter because

of the weight consideration. So one thing we're working on is how to

make radiation-shielding materials from the elements that we find

there," says Sheila Thibeault, a scientist at LaRC who specializes

in radiation shielding. "We

can't take most of the materials with us for a long-term shelter because

of the weight consideration. So one thing we're working on is how to

make radiation-shielding materials from the elements that we find

there," says Sheila Thibeault, a scientist at LaRC who specializes

in radiation shielding.

Right: Astronauts setting up

camp on Mars will need protection from space radiation. Image credit: Frassanito

and Associates, Inc.

One possible solution is "Mars

bricks." Thibeault explains: "Astronauts could produce

radiation-resistant bricks from materials available locally on Mars, and

use them to build shelters." They might, for example, combine the

sand-like "regolith" that covers the Martian surface with a

polymer made on-site from carbon dioxide and water, both abundant on the

red planet. Zapping this mixture with microwaves creates plastic-looking

bricks that double as good radiation shielding.

"By using microwaves, we can make these bricks quickly using very

little energy or equipment," she explains. "And the polymer we

would use adds to the radiation-shielding properties of the regolith."

Mars shelters would need the reliability of self-sensing materials, the

durability of self-healing materials, and the weight savings of

multi-functional materials. In other words, a house on Mars and a good

spacecraft need many of the same things. All of these are being

considered by researchers, Thibeault says.

The folks back home

Mind-boggling advanced materials will come in handy on Earth, too.

"NASA's research is certainly focused on aerospace vehicles,"

notes Anna McGowan, manager of NASA's Morphing Project (an advanced

materials research effort at the Langley Research Center).

"However, the basic science could be used in many other areas.

There could be millions of spin-offs."

|

'BigDog' Robot Joins U.S. Military

It

appears that DARPA (US Defense

Advanced Research Projects Agency) has been busy

since we last wrote about their research into

morphing metals. Their

latest invention is called 'BigDog', which is a

quadruped robot that walks, runs, and climbs on

rough terrain and carries heavy loads. BigDog is

powered by a gasoline engine that drives a

hydraulic actuation system. It's legs are

articulated like an animal’s, and have compliant

elements that absorb shock and recycle energy

from one step to the next. BigDog is the size of

a large dog or small mule, measuring 1 meter

long, 0.7 meters tall and 75 kg in weight.

It

appears that DARPA (US Defense

Advanced Research Projects Agency) has been busy

since we last wrote about their research into

morphing metals. Their

latest invention is called 'BigDog', which is a

quadruped robot that walks, runs, and climbs on

rough terrain and carries heavy loads. BigDog is

powered by a gasoline engine that drives a

hydraulic actuation system. It's legs are

articulated like an animal’s, and have compliant

elements that absorb shock and recycle energy

from one step to the next. BigDog is the size of

a large dog or small mule, measuring 1 meter

long, 0.7 meters tall and 75 kg in weight.

BigDog is

being developed by Boston Dynamics with the goal

of creating robots that have rough-terrain

mobility that can take them anywhere on Earth

that people and animals can go.

Marc Raibert, the president of Boston Dynamics,

said: "Internal force sensors detect the ground

variations and compensate for them. And BigDog's

active balance allows it to maintain stability

when we disturb it."

Current models of BigDog are remote-controlled

from army bases by commanders. However it is

thought that future versions will be built with

eye-like sensors that allow it to become

"unleashed" by making intelligent decisions

about a journey. The program is

funded by DARPA.

For More Information

We were originally going to keep DARPA's

identity secret for a while for two reasons. The first reason was to keep this

story exclusive, and two, to stop other sites from simply going to DARPA and

beating us in releasing this interesting story that we have spent investigating

over the last 6 weeks. However, due to the wealth of information on the

DARPA site, and the lack of space on Cosmic Conspiracies server, we simply

cannot bring as much of the material that we would like to and therefore we have

decided to release the name of the main organisation involved so that you could

all check out the DARPA site for yourselves.

The URL is http://www.darpa.mil/

Also check out

http://science.nasa.gov/headlines/y2001/ast01mar_1.htm

CLICK ON THEIR SEARCH ENGINE ON

THE DARPA SITE AND TYPE IN THE WORD CHAP.

THERE ARE OVER 130 DOCUMENTS

WHEN WE LAST CHECKED, SO BE PREPARED TO STAY FOR A WHILE.

REMEMBER

WHERE YOU HEARD IT FIRST!

© Andy Lloyd, Dave and

Martin Cosnette

9th December 2001. Updated 10th February 2009

It

appears that DARPA (US Defense

Advanced Research Projects Agency) has been busy

since we last wrote about their research into

morphing metals. Their

latest invention is called 'BigDog', which is a

quadruped robot that walks, runs, and climbs on

rough terrain and carries heavy loads. BigDog is

powered by a gasoline engine that drives a

hydraulic actuation system. It's legs are

articulated like an animal’s, and have compliant

elements that absorb shock and recycle energy

from one step to the next. BigDog is the size of

a large dog or small mule, measuring 1 meter

long, 0.7 meters tall and 75 kg in weight.

It

appears that DARPA (US Defense

Advanced Research Projects Agency) has been busy

since we last wrote about their research into

morphing metals. Their

latest invention is called 'BigDog', which is a

quadruped robot that walks, runs, and climbs on

rough terrain and carries heavy loads. BigDog is

powered by a gasoline engine that drives a

hydraulic actuation system. It's legs are

articulated like an animal’s, and have compliant

elements that absorb shock and recycle energy

from one step to the next. BigDog is the size of

a large dog or small mule, measuring 1 meter

long, 0.7 meters tall and 75 kg in weight.

Cosmic

Conspiracies would like to share with you some remarkable information

relating to current cutting-edge technological research being conducted on

behalf of the U.S. military that we believe could be connected to the materials

found from the Roswell crash. We are stunned by it, not least because of how

freely available much of the data is on the Internet. Finding this freely

available material, however, is extremely difficult unless you are aware of the

specific keywords being utilised, or, as in our case, you have a researcher of

the calibre of Martin Cosnette. This is not common

knowledge, despite the amazing jump in technology implied by the rapid advances

being made right now.

Cosmic

Conspiracies would like to share with you some remarkable information

relating to current cutting-edge technological research being conducted on

behalf of the U.S. military that we believe could be connected to the materials

found from the Roswell crash. We are stunned by it, not least because of how

freely available much of the data is on the Internet. Finding this freely

available material, however, is extremely difficult unless you are aware of the

specific keywords being utilised, or, as in our case, you have a researcher of

the calibre of Martin Cosnette. This is not common

knowledge, despite the amazing jump in technology implied by the rapid advances

being made right now.

We have accessed over 130

documents so far, including pictures and video footage, budgets and names of

project leaders and their departments/companies involved. This technology is

being incorporated into prototype applications right now. These include morphing

aeroforms in Unmanned Aerial Vehicles (UAVs) and fighter aircraft, morphing

rotor-blades in helicopters, in-flight navigation, guidance and control systems

for small missiles, satellite technology (especially with respect to optical

systems), and sonar-absorbing materials for submarines. If you watch the video

animation above, you will see that a plane with flappable wings is one of the

goals of this project.

We have accessed over 130

documents so far, including pictures and video footage, budgets and names of

project leaders and their departments/companies involved. This technology is

being incorporated into prototype applications right now. These include morphing

aeroforms in Unmanned Aerial Vehicles (UAVs) and fighter aircraft, morphing

rotor-blades in helicopters, in-flight navigation, guidance and control systems

for small missiles, satellite technology (especially with respect to optical

systems), and sonar-absorbing materials for submarines. If you watch the video

animation above, you will see that a plane with flappable wings is one of the

goals of this project.

Now, we are not

omnipotent. There may be some people out there who know all about this

already, but the feedback we have received indicates that, to the vast majority

of people out there, this is entirely new material. No one else is carrying this

story except Cosmic Conspiracies. If that’s because they don’t think it’s

important, then that’s up to them. We have been interested in UFOlogy for

some considerable time, and read a lot of material, both in magazines and

on-line, and this material is news to us. We remain excited by it, not

necessarily because it individually blows the lid off the ‘seeding technology’

business between the US Military and private industry/academic research labs,

but because, taken in the context of the claims of Colonel Philip Corso and

others, it adheres to a pattern that is noticeable, and significant.

Now, we are not

omnipotent. There may be some people out there who know all about this

already, but the feedback we have received indicates that, to the vast majority

of people out there, this is entirely new material. No one else is carrying this

story except Cosmic Conspiracies. If that’s because they don’t think it’s

important, then that’s up to them. We have been interested in UFOlogy for

some considerable time, and read a lot of material, both in magazines and

on-line, and this material is news to us. We remain excited by it, not

necessarily because it individually blows the lid off the ‘seeding technology’

business between the US Military and private industry/academic research labs,

but because, taken in the context of the claims of Colonel Philip Corso and

others, it adheres to a pattern that is noticeable, and significant.

The power to drive the actuators is

portable, and could, for instance, take the form of a back-pack worn by soldiers

who are powered lower body exoskeletons. But there are hints in the

research texts alluding to truly 'intelligent' materials. We consider it likely

that the modular architecture described fits in with the general concepts of

'nano-technology'. That is, the intelligent ‘biological’ actuators have

purpose-built machines within it designed at the molecular level.

The power to drive the actuators is

portable, and could, for instance, take the form of a back-pack worn by soldiers

who are powered lower body exoskeletons. But there are hints in the

research texts alluding to truly 'intelligent' materials. We consider it likely

that the modular architecture described fits in with the general concepts of

'nano-technology'. That is, the intelligent ‘biological’ actuators have

purpose-built machines within it designed at the molecular level.

6. Finally, compact hybrid actuators are

being developed to reduce levels of self-noise, particularly with respect to the

sonar detectibility of torpedoes. Mention is also made of Unmanned Underwater

Vehicles (I presume this is what is meant by UUV's). This technology seems

to represent a kind of 'stealth' characteristic for underwater vehicles and

weapon systems. One wonders whether a similar system has been applied to ground

or air vehicles to effectively 'cloak' them on an auditory level?

6. Finally, compact hybrid actuators are

being developed to reduce levels of self-noise, particularly with respect to the

sonar detectibility of torpedoes. Mention is also made of Unmanned Underwater

Vehicles (I presume this is what is meant by UUV's). This technology seems

to represent a kind of 'stealth' characteristic for underwater vehicles and

weapon systems. One wonders whether a similar system has been applied to ground

or air vehicles to effectively 'cloak' them on an auditory level?

"This

phenomenal strength comes from the molecular structure of nanotubes,"

explains Dennis Bushnell, a chief scientist at Langley Research Center (LaRC),

NASA's Center of Excellence for Structures and Materials. They look a

bit like chicken-wire rolled into a cylinder with carbon atoms sitting

at each of the hexagons' corners. Typically nanotubes are about 1.2 to

1.4 nanometers across (a nanometer is one-billionth of a meter), which

is only about 10 times the radius of the carbon atoms themselves.

"This

phenomenal strength comes from the molecular structure of nanotubes,"

explains Dennis Bushnell, a chief scientist at Langley Research Center (LaRC),

NASA's Center of Excellence for Structures and Materials. They look a

bit like chicken-wire rolled into a cylinder with carbon atoms sitting

at each of the hexagons' corners. Typically nanotubes are about 1.2 to

1.4 nanometers across (a nanometer is one-billionth of a meter), which

is only about 10 times the radius of the carbon atoms themselves. Right:

The tensile strength of carbon nanotubes greatly exceeds that of

other high-strength materials. Note that each increment on the vertical

axis is a power of 10. [

Right:

The tensile strength of carbon nanotubes greatly exceeds that of

other high-strength materials. Note that each increment on the vertical

axis is a power of 10. [